Zinc Plating Chrome Alternatives

Hofmann’s vertical integration doesn’t stop at the fabrication department! We’re the only producer in the United States to offer in-house zinc plating and powder coating to our customers.

Problem:

Brite plated parts are attractive, durable and provide corrosion protection. For U.S. manufacturers of products such as housewares, hardware, or office equipment, lighting products, and furniture, domestically-sourced chrome plated products are often cost-prohibitive.

Solution

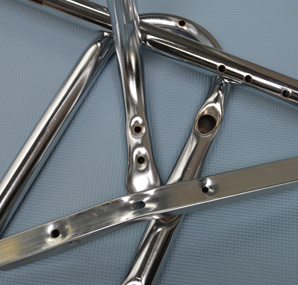

To satisfy consumer desire for a chrome-like appearance on items like shower curtain rods, organizers, shelving, and other products, Hofmann undertook intensive research and development to engineer a plating process that produced a similar finish to chrome plating but at substantially lower applied cost. In addition to resembling the appearance of chrome, we wanted our zinc finish to offer the same functional advantages, such as corrosion resistance and ease of cleaning.

Zinc plating is commonly used for enhancing corrosion resistance, but the finish is typically dull. Beginning in 1974, Hofmann invested in a state-of-the-art zinc plating line and collaborated with chemical engineers and other specialists in surface finishing to find an application method that would brighten the plated finish while preserving its performance properties. The zinc plated finish that we produce using an acid chloride bath over a bright steel substrate is attractive, durable, and much less expensive than chrome.

Results

We provide ASTM B117-compliant zinc plated finishes with the aesthetic appeal of chrome but at a substantially lower price. As the only steel tube manufacturer with an in-house plating department, we furnish manufacturers of consumer goods, hotel furnishings, automotive parts, and office equipment with the ability to plate lengths of up to 120” brightly finished tube that exceeds industry standards for corrosion resistance. This aesthetic, durable, and affordable finish is the result of our continuous pursuit of process improvement and production efficiency to help customers control costs and continue to manufacture and sell goods in the United States.

Stocking Program Highlights

- Project Name & Description

- Zinc Plating – Chrome Alternative

- Capabilities Applied/Processes

- Steel Tube Manufacturing, Zinc Plating

- Equipment Used to Manufacture Part

- Hofmann’s Automated Zinc Plating Line

- Overall Part Dimensions

- Lengths up to 120″

- Material Used

- Acid Chloride Zinc Plating, Brite Steel

- Material Finish

- Brite Zinc Plating

- Industry for Use

- Housewares, Hardware, Office Furniture, Hotel Furnishings, Juvenile Products, Automotive, Recreation Industries

- Standards Met

- ASTM B117